Rivian is arguably the most successful EV startup in the US, although it's far from coming out of the woods. The company burns its cash reserves like there's no tomorrow and only a radical change in strategy can save it from following Lordstown and Fisker into nothingness. Rivian is reconsidering its options with a new strategy copied from Tesla's book down to autonomous driving and manufacturing tricks.

Although Rivian looks like a promising startup with compelling vehicles and solid plans to become profitable, everything can come tumbling down in the blink of an eye. Having started its journey with one of the fattest cash reserves in the industry, Rivian hasn't paid much attention to financial discipline. Thanks to a massive investment from Amazon, all it had to do was focus on delivering the vehicles it promised and scale up operations.

However, with a tough economic environment looming and supply chain bottlenecks, Rivian production dwindled for much of 2022. This accelerated the bleeding, as Rivian had to spend its reserves to keep operating. Its vehicles were built with many off-the-shelf parts, and suppliers were more than happy to squeeze the ailing startup. The company CEO, RJ Scaringe, used to think big, planning a second factory in Georgia before the current one in Illinois reached peak capacity. As Elon Musk predicted in June 2022, it was a disaster.

Thankfully, the management team woke up to the new reality and took corrective action. Rivian began developing its own parts in a push for vertical integration that mirrored Tesla's strategy. The Normal, Illinois, factory was overhauled to improve manufacturing efficiency, while the second plant in Georgia was put on the back burner. Finally, Rivian reengineered its R1 vehicle lineup to save costs and stop the money bleeding.

Although Rivian reiterated that it would turn a modest gross profit per vehicle by the end of the year, this is far from enough to become profitable. In the first quarter, Rivian lost almost $40K for every vehicle sold. During the June 27 Investor Day, the company's CFO, Claire McDonough, admitted that Rivian would not have positive earnings before taxes (EBITDA) until 2027. However, she offered no date for net profitability.

This means that Rivian is very far from becoming cash flow positive and might never reach that point if it goes bankrupt in the process. The startup has less than $8 billion left in its coffers, and it burns roughly $1.5 billion per quarter with no sign of slowing. If anything, things got worse after Q3 2023, and the company's executives warned that Q2 2024 would be brutal. The recently announced deal with Volkswagen might offer a temporary lifeline, but it won't necessarily represent the life vest Rivian might hope for.

This is why the new strategy Rivian unveiled during Investor Day is instrumental in staying afloat through 2027 as the money runs out. Page by page, the new roadmap seems diligently copied from one of Tesla's books. Here's everything Rivian announced for its future R2/R3 vehicles. Hopefully, it won't dry out its cash reserves before implementing these technological advancements and cost optimizations.

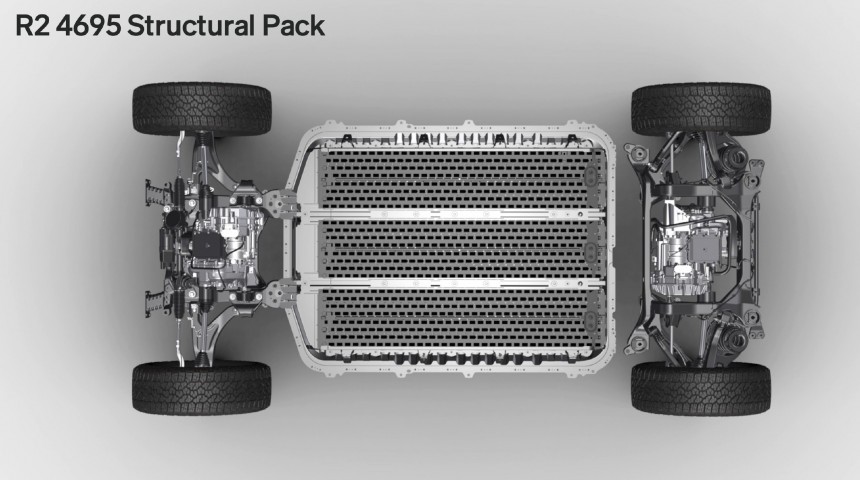

It has already started to implement these changes with the refreshed R1 vehicles. Rivian already replaced 17 structural pieces with high-pressure die-casting in the battery pack of the 2025 R1S and R1T EVs. However, the biggest change comes with the R2, which is set to start production in 2026. The Rivian R2 will feature a structural battery with 4695 cells supplied by Samsung SDI, the same company that will produce the battery cells for BMW Neue Klasse EVs. The R2 and R3 also adopt a floor-to-pack design similar to Tesla's.

The vehicle body design has also been optimized, starting with the R1 refresh. Rivian's Gen 2 vehicle bodies have 65 fewer parts and 1,500 fewer connection points, allowing the startup to improve the number of jobs per hour (JPH) by 30%. However, the R2 model will take this to a new level thanks to design optimizations and adopting large high-pressure die-casting parts, or megacastings in Tesla's lingo. Thanks to this technique, the R2 rear underbody will have 96% fewer parts. Similar savings are possible in the cross-beam bar and other body sections.

Rivian also gives the R2 doors as an example of what can be achieved. Since the compact EVs are mass-market models, Rivian has simplified construction by trimming 65% of the parts compared to the R1 vehicles. Similarly, the front suspension adopts a simpler McPherson strut and passive coils instead of the sophisticated double-wishbone suspension with electro-hydraulic adjustable damping in the R1 vehicles.

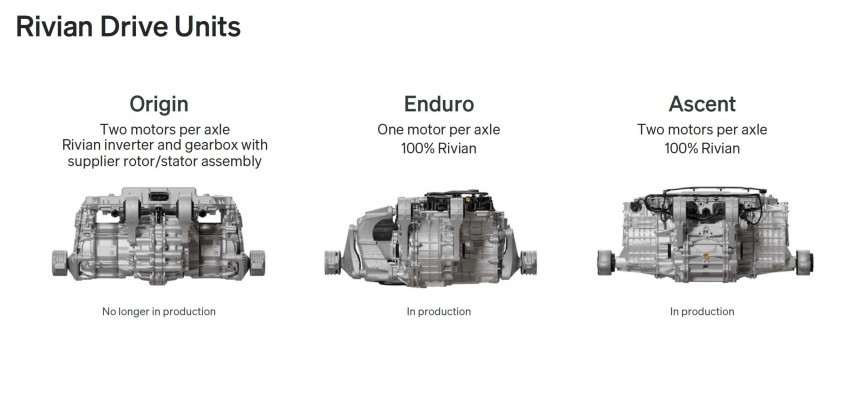

Rivian has further developed the Enduro drive units into the Ascent unit, which comprises two Enduro motors per axle. The Ascent drive units are used in the tri-motor R1S and R1T and will also be included in the Ascent Quad variants starting in 2025. The Ascent drive unit features a redesigned inverter with welded high-voltage joints. This offers lower joint resistance and improved manufacturing efficiency thanks to fewer fastening stations on the production line.

The Ascent drive units integrate the housing mounts, offering improved stiffness, while dual isolated bushings are meant to improve NVH. The motors adopt hairpin windings for higher power density and lower costs. Finally, they use direct oil cooling for the stator and rotor, offering improved thermal performance. The Ascent drive units are responsible for the increased performance and longer range in the refreshed R1 vehicles compared to the first-generation models.

However, Rivian intends to make an important step with the launch of the R2 and R3. The compact EVs will use second-generation Enduro motors, with optimized packaging and integrated side-mounted inverter. Rivian calls it Maximus, and it's more compact and even more efficient. The EV startup claims 30% cost savings compared to the original Enduro motors. This is a direct result of the 30% reduction in labor, 11% reduction in engineered parts, and 32% reduction in drive unit fasteners.

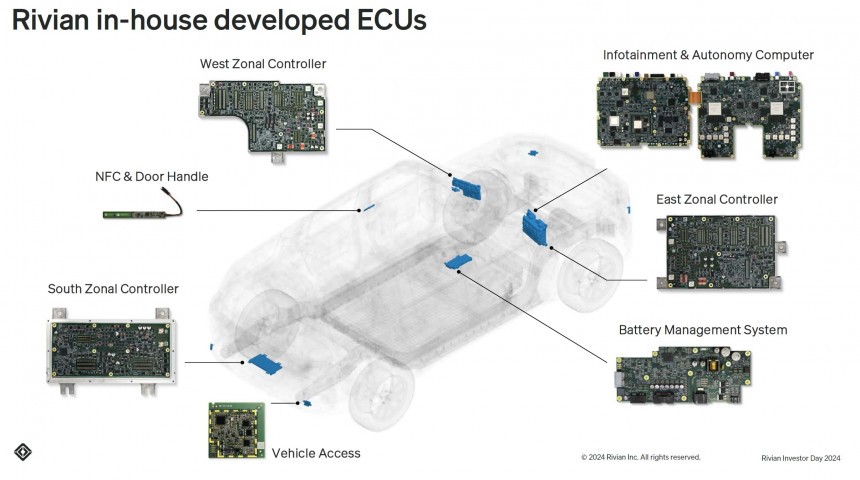

You can't have software-defined vehicles (SDV) when your electronic architecture is a mish-mash of electronic components. This makes over-the-air updates virtually impossible because chips from different suppliers must be updated separately, if at all possible. This is why Rivian opted from the beginning to design its electronic chips in-house.

With the R1 refresh, Rivian has moved to a zonal electronics architecture, simplifying manufacturing and offering important benefits thanks to improved software support. Instead of 17 ECUs in the Gen 1 vehicles, the refreshed R1 models have only seven in-house designed controllers. These include three zonal controllers (named West, East, and South), the Infotainment and Autonomy computer, and the battery management system. Two more controllers are used for vehicle access, as well as the NFC and door handle.

The new Autonomy Computer provides a 4:1 chip consolidation compared to the Gen 1 ECUs. The unit offers ten times the AI compute capability of the Gen 1 computer, or up to 250 TOPS (trillion operations per second), thanks to dual Nvidia Drive Orin processors. That's on the same compute power level as Tesla's Hardware 4 Autopilot computer.

The upgraded sensor package features 11 cameras, five radars, and AI prediction technology for advanced safety and driving assistance. These include higher resolution cameras (3 MP and 8 MP with HDR capability) and a high resolution (imaging) front radar. All the sensors feed data into the Autonomy Computer via high-speed interfaces, with 6 Gbps bandwidth for cameras, 11.2 Gbps chip-to-chip, and a 10 Gbps Ethernet connection.

Rivian's Autonomy Platform has been optimized for redundancy and scalability, allowing the use of different sensor technologies on the same core machine-learning stack. This should expedite the launching of new vehicle models and variants by transferring prior learning to new sensors. Hopefully, this will avoid embarrassments, such as the Tesla Cybertruck not offering basic driver assistance features seven months after launch.

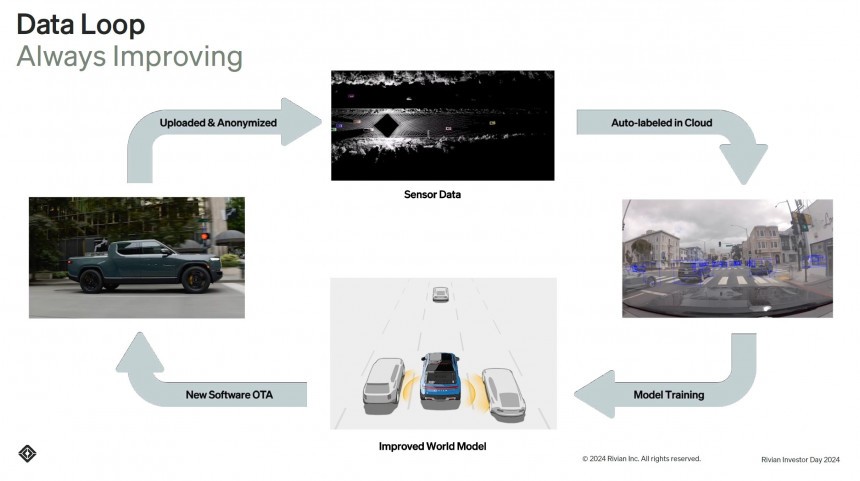

The images recorded by vehicle cameras are anonymized and uploaded to the cloud, where they are auto-labeled and used for model training. Subsequently, the improved world model is downloaded to vehicles via OTA software updates. That's exactly how Tesla Full Self-Driving is developed and improved.

Rivian says it processes over 5.6 million simulations. This is still far from Tesla's capabilities, as Rivian has a much smaller vehicle fleet. It also lacks processing power, an aspect that will not change soon. Considering its financial situation, building massive data centers is out of reach for the EV startup. This is why it will start small with its Autonomy Platform+, which aims to offer capabilities that are on par with Tesla's Enhanced Autopilot.

From next year, Rivian will launch Enhanced Highway Assist with on-ramp to off-ramp navigation. There are no current plans to expand automated driving features to city streets, like Tesla FSD. However, the way Rivian explained its autonomous driving efforts sounds pretty similar to Tesla's neural networks. Rivian's Autonomy Platform uses end-to-end training to learn and improve over time.

Although the Rivian Adventure Network (the name of Rivian's charging network) has nowhere near the scale of the Tesla Supercharger, it offers unique capabilities. One of them is that Rivian chargers are installed in areas with fewer charging opportunities, often outside the beaten path, which aligns with Rivian's adventurous profile. This makes it less redundant, especially as Rivian owners can access Tesla Superchargers and third-party charging networks.

Another characteristic of Rivian chargers is that they are 800-volt-capable, even though Rivian doesn't have an 800-volt EV model in its lineup. The charging stalls support charging at up to 300 kW, although current sites offer 200 kW. Like Tesla, Rivian developed its charging hardware in-house, ensuring seamless operation for Rivian vehicles.

However, the chargers are also compatible with non-Rivian EVs, paving the way for opening up the Rivian Adventure Network to other EV brands later this year. Although the chargers are still not fitted with a NACS plug, this will be offered from next year. Hopefully, this means that the Tesla Cybertruck, which features an 800-volt architecture, will be able to charge at full speed at Rivian's chargers.

Rivian will not only start building new charging stations using the new equipment, but it will also retrofit its current sites. Like Tesla, which started optimizing its Supercharger stations for towing vehicles, Rivian Adventure Network will prioritize pull-through charging stalls for the new locations.

However, with a tough economic environment looming and supply chain bottlenecks, Rivian production dwindled for much of 2022. This accelerated the bleeding, as Rivian had to spend its reserves to keep operating. Its vehicles were built with many off-the-shelf parts, and suppliers were more than happy to squeeze the ailing startup. The company CEO, RJ Scaringe, used to think big, planning a second factory in Georgia before the current one in Illinois reached peak capacity. As Elon Musk predicted in June 2022, it was a disaster.

Thankfully, the management team woke up to the new reality and took corrective action. Rivian began developing its own parts in a push for vertical integration that mirrored Tesla's strategy. The Normal, Illinois, factory was overhauled to improve manufacturing efficiency, while the second plant in Georgia was put on the back burner. Finally, Rivian reengineered its R1 vehicle lineup to save costs and stop the money bleeding.

This means that Rivian is very far from becoming cash flow positive and might never reach that point if it goes bankrupt in the process. The startup has less than $8 billion left in its coffers, and it burns roughly $1.5 billion per quarter with no sign of slowing. If anything, things got worse after Q3 2023, and the company's executives warned that Q2 2024 would be brutal. The recently announced deal with Volkswagen might offer a temporary lifeline, but it won't necessarily represent the life vest Rivian might hope for.

This is why the new strategy Rivian unveiled during Investor Day is instrumental in staying afloat through 2027 as the money runs out. Page by page, the new roadmap seems diligently copied from one of Tesla's books. Here's everything Rivian announced for its future R2/R3 vehicles. Hopefully, it won't dry out its cash reserves before implementing these technological advancements and cost optimizations.

Optimized vehicle architecture: megacastings, structural battery

Rivian has its eyes on the ball, and in this case, the ball is represented by its ability to cut costs. This is why the startup has been paying close attention to Tesla's latest announcements. Even though the EV market leader has moved away from manufacturing and is now chasing artificial intelligence and robotics, it doesn't mean its initial strategy was incorrect. Rivian certainly appreciates it, which is why we'll see a lot of inspiration drawn from Tesla's abandoned strategy.The vehicle body design has also been optimized, starting with the R1 refresh. Rivian's Gen 2 vehicle bodies have 65 fewer parts and 1,500 fewer connection points, allowing the startup to improve the number of jobs per hour (JPH) by 30%. However, the R2 model will take this to a new level thanks to design optimizations and adopting large high-pressure die-casting parts, or megacastings in Tesla's lingo. Thanks to this technique, the R2 rear underbody will have 96% fewer parts. Similar savings are possible in the cross-beam bar and other body sections.

Rivian also gives the R2 doors as an example of what can be achieved. Since the compact EVs are mass-market models, Rivian has simplified construction by trimming 65% of the parts compared to the R1 vehicles. Similarly, the front suspension adopts a simpler McPherson strut and passive coils instead of the sophisticated double-wishbone suspension with electro-hydraulic adjustable damping in the R1 vehicles.

In-house developed drive units: from Enduro to Ascent to Maximus

In-house development of electric motors has proved Rivian expertise in designing high-efficiency drive units. The Enduro motors were first used in the EDV/RCV vans and were later introduced in the R1 passenger vehicles with the Dual-Motor variants in 2023. With the launch of the refreshed R1 models, the Enduro motors have replaced Bosch-supplied units in all vehicle variants.The Ascent drive units integrate the housing mounts, offering improved stiffness, while dual isolated bushings are meant to improve NVH. The motors adopt hairpin windings for higher power density and lower costs. Finally, they use direct oil cooling for the stator and rotor, offering improved thermal performance. The Ascent drive units are responsible for the increased performance and longer range in the refreshed R1 vehicles compared to the first-generation models.

However, Rivian intends to make an important step with the launch of the R2 and R3. The compact EVs will use second-generation Enduro motors, with optimized packaging and integrated side-mounted inverter. Rivian calls it Maximus, and it's more compact and even more efficient. The EV startup claims 30% cost savings compared to the original Enduro motors. This is a direct result of the 30% reduction in labor, 11% reduction in engineered parts, and 32% reduction in drive unit fasteners.

Hardware electronics: ECU consolidation and a new zonal architecture

The first generation of Rivian R1 vehicles was already more advanced than anything legacy carmakers produced. Instead of relying on off-the-shelf electronic control units (ECUs), Rivian developed its controllers in-house. This healthy foundation allowed it to become a software powerhouse comparable only to Tesla.With the R1 refresh, Rivian has moved to a zonal electronics architecture, simplifying manufacturing and offering important benefits thanks to improved software support. Instead of 17 ECUs in the Gen 1 vehicles, the refreshed R1 models have only seven in-house designed controllers. These include three zonal controllers (named West, East, and South), the Infotainment and Autonomy computer, and the battery management system. Two more controllers are used for vehicle access, as well as the NFC and door handle.

The new Autonomy Computer provides a 4:1 chip consolidation compared to the Gen 1 ECUs. The unit offers ten times the AI compute capability of the Gen 1 computer, or up to 250 TOPS (trillion operations per second), thanks to dual Nvidia Drive Orin processors. That's on the same compute power level as Tesla's Hardware 4 Autopilot computer.

The upgraded sensor package features 11 cameras, five radars, and AI prediction technology for advanced safety and driving assistance. These include higher resolution cameras (3 MP and 8 MP with HDR capability) and a high resolution (imaging) front radar. All the sensors feed data into the Autonomy Computer via high-speed interfaces, with 6 Gbps bandwidth for cameras, 11.2 Gbps chip-to-chip, and a 10 Gbps Ethernet connection.

Software: end-to-end AI paves the way to autonomous driving

Rivian has been praised for its software competency, and its timely over-the-air software updates have encouraged people to compare it to Tesla. They will have more reasons to do that in the future, as Rivian is adopting a similar strategy with artificial intelligence in pursuit of autonomous driving.The images recorded by vehicle cameras are anonymized and uploaded to the cloud, where they are auto-labeled and used for model training. Subsequently, the improved world model is downloaded to vehicles via OTA software updates. That's exactly how Tesla Full Self-Driving is developed and improved.

Rivian says it processes over 5.6 million simulations. This is still far from Tesla's capabilities, as Rivian has a much smaller vehicle fleet. It also lacks processing power, an aspect that will not change soon. Considering its financial situation, building massive data centers is out of reach for the EV startup. This is why it will start small with its Autonomy Platform+, which aims to offer capabilities that are on par with Tesla's Enhanced Autopilot.

From next year, Rivian will launch Enhanced Highway Assist with on-ramp to off-ramp navigation. There are no current plans to expand automated driving features to city streets, like Tesla FSD. However, the way Rivian explained its autonomous driving efforts sounds pretty similar to Tesla's neural networks. Rivian's Autonomy Platform uses end-to-end training to learn and improve over time.

Rivian's charging infrastructure is expanding

This is one of the most important areas where Rivian still has a lot to do. From the get-go, Rivian followed in Tesla's footsteps but always considered the improvements it might bring to the table. However, Rivian has been slow in expanding its charging network despite ambitious plans to build over 3,500 DC fast chargers at 600 locations across the US and Canada. As of February, the EV startup counted only 400 DC fast chargers at 67 locations in the US. However, Rivian owners can now access over 15,000 Tesla Supercharger locations with the Rivian NACS adapter.Another characteristic of Rivian chargers is that they are 800-volt-capable, even though Rivian doesn't have an 800-volt EV model in its lineup. The charging stalls support charging at up to 300 kW, although current sites offer 200 kW. Like Tesla, Rivian developed its charging hardware in-house, ensuring seamless operation for Rivian vehicles.

However, the chargers are also compatible with non-Rivian EVs, paving the way for opening up the Rivian Adventure Network to other EV brands later this year. Although the chargers are still not fitted with a NACS plug, this will be offered from next year. Hopefully, this means that the Tesla Cybertruck, which features an 800-volt architecture, will be able to charge at full speed at Rivian's chargers.

Rivian will not only start building new charging stations using the new equipment, but it will also retrofit its current sites. Like Tesla, which started optimizing its Supercharger stations for towing vehicles, Rivian Adventure Network will prioritize pull-through charging stalls for the new locations.