Mercedes and Microsoft have announced a collaboration to make vehicle production more efficient and sustainable. The automaker is connecting around 30 passenger car plants across the globe to Microsoft Cloud, further digitalizing the enterprise.

Joerg Burzer, Member of the Board of Management of Mercedes-Benz Group AG, said, “This new partnership between Microsoft and Mercedes-Benz will make our global production network more intelligent, sustainable and resilient in an era of geopolitical and macroeconomic challenges. The ability to predict and prevent problems in production and logistics will become a key competitive advantage as we go all electric.”

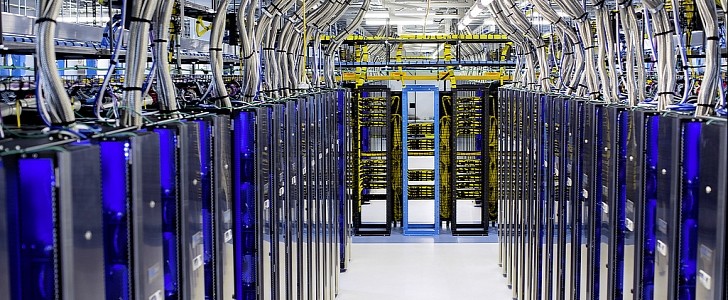

The MO360 Data Platform is the evolution of the Mercedes-Benz digital production ecosystem MO360. Standardized on Microsoft Azure, teams can use it to efficiently prioritize production resources toward electric and Top-End vehicles. The platform will also provide cloud computing power that helps the automaker run AI (artificial intelligence) and analytics. It’s already available in EMEA (Europe, Middle East, and Africa) and will be supplied to the U.S. and China.

So, why is this collaboration critical for Mercedes-Benz? It democratizes technology and data in manufacturing. Several points will boost production for the automaker, and I will tackle them below.

A virtual replica of the company’s manufacturing process can be created, gathering insights from all production steps, such as planning, assembly, logistics, and others. By running the virtual simulation, processes can be optimized, and manufacturing will be accelerated.

Using the centralized data platform, resources can be dynamically allocated across plants, and supply chain bottlenecks can be quickly identified and resolved.

As the world is heading towards an electrified future, shortages in components and delivery delays can be addressed, and production scenarios can be explored based on the availability of parts and equipment. Productivity gains of 20% in passenger car production are expected by 2025.

Mercedes-Benz has implemented an analytics tool that monitors and reduces the ecological footprint during vehicle production. As the company aims to be carbon-neutral by 2039, this is a crucial step. The tool allows teams to track and forecast carbon emissions, water and energy usage, and waste management. By using centralized data, the right decisions can be made. Moreover, the company plans on covering over 70% of its energy needs through renewable sources by 2030. It will achieve this result by expanding solar and wind power at its sites.

Mercedes-Benz production staff have access to the MO360 Data Platform through a self-service portal available on all company devices. The data that governs the entire manufacturing process is just a few touches away, making it very accessible.

The MO360 Data Platform is the evolution of the Mercedes-Benz digital production ecosystem MO360. Standardized on Microsoft Azure, teams can use it to efficiently prioritize production resources toward electric and Top-End vehicles. The platform will also provide cloud computing power that helps the automaker run AI (artificial intelligence) and analytics. It’s already available in EMEA (Europe, Middle East, and Africa) and will be supplied to the U.S. and China.

So, why is this collaboration critical for Mercedes-Benz? It democratizes technology and data in manufacturing. Several points will boost production for the automaker, and I will tackle them below.

A virtual replica of the company’s manufacturing process can be created, gathering insights from all production steps, such as planning, assembly, logistics, and others. By running the virtual simulation, processes can be optimized, and manufacturing will be accelerated.

Using the centralized data platform, resources can be dynamically allocated across plants, and supply chain bottlenecks can be quickly identified and resolved.

As the world is heading towards an electrified future, shortages in components and delivery delays can be addressed, and production scenarios can be explored based on the availability of parts and equipment. Productivity gains of 20% in passenger car production are expected by 2025.

Mercedes-Benz has implemented an analytics tool that monitors and reduces the ecological footprint during vehicle production. As the company aims to be carbon-neutral by 2039, this is a crucial step. The tool allows teams to track and forecast carbon emissions, water and energy usage, and waste management. By using centralized data, the right decisions can be made. Moreover, the company plans on covering over 70% of its energy needs through renewable sources by 2030. It will achieve this result by expanding solar and wind power at its sites.

Mercedes-Benz production staff have access to the MO360 Data Platform through a self-service portal available on all company devices. The data that governs the entire manufacturing process is just a few touches away, making it very accessible.