You all know what a heat shield is: a key component on a spacecraft, meant to protect it from the extreme temperatures of atmospheric re-entry. But did you know that NASA has invented a new type of heat shield material that's supposed to revolutionize not only space exploration, but other fields of human activity as well?

But first, a quick look into why a returning spacecraft (or one that descends to the surface of another planet) is in danger of being utterly destroyed by re-entry.

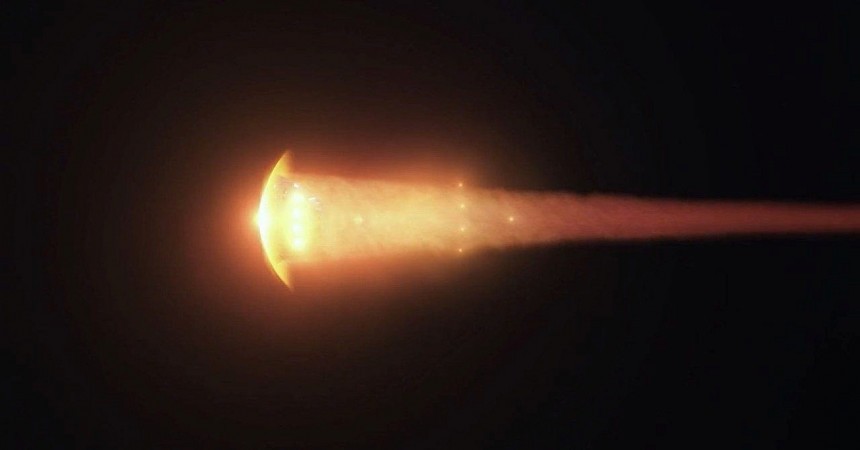

As it comes down from space and reaches the upper layers of a planet's atmosphere, the spacecraft makes the transition from complete void to an environment that opposes it moving forward.

Because the speed of re-entry is quite high (about 25,000 mph / 40,233 kph in the case of a ship returning from the Moon), the spacecraft rubs against air and other gases in such a way that the area around the ship is exposed to extreme temperatures: as much as 5,000 degrees Fahrenheit (2,760 Celsius). For reference, that's twice as hot as molten lava, and half the temperature on the surface of the Sun.

We've all seen what a problem with the heat shield can cause during the Columbia Space Shuttle disaster. As it departed our world, a piece of Columbia's insulating foam on the external fuel tank broke loose and struck the left wing. The heat-resistant tiles there were damaged, and upon returning from the International Space Station (ISS), they failed, causing the ship to burn up in the atmosphere with seven crew members on board.

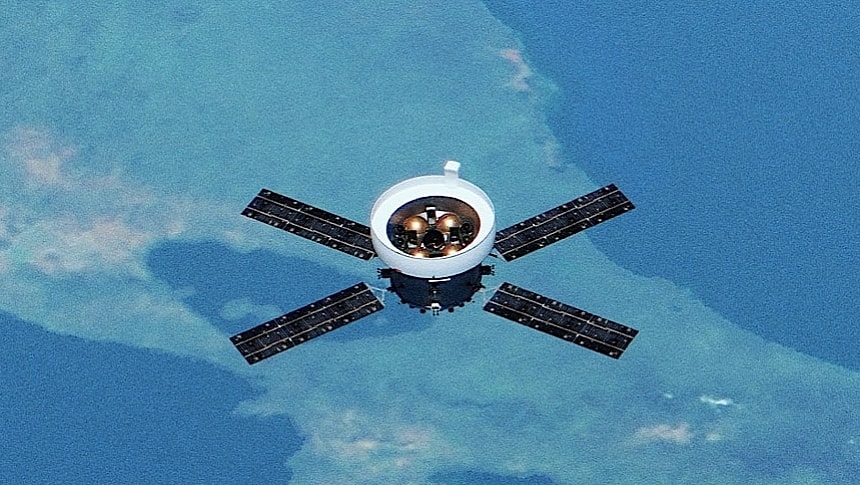

No other disasters linked to the heat shield have happened since, and NASA doesn't want it ever to happen again. And that's why, back in 2017, the agency and a series of partners started working on a new kind of thermal protection material for the Orion spacecraft of the Artemis program.

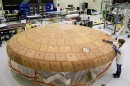

The heat shield Orion will use to protect itself is centered around something called Avcoat, an evolution of the material that has been around since the days of the Apollo program.

Avcoat is technically an epoxy resin fixed in a fiberglass honeycomb matrix with a series of additives, and it's not something that can last forever during re-entry. The stuff is called an ablator because it burns off in a gradual and controlled manner, detaching from the ship and taking some of the heat with it.

The Avcoat layer on the Orion measures between one and three inches thick (2.5 to 7.6 cm), and it goes over the carbon fiber skin of the heat shield itself.

But Orion, like any other spaceship in existence, is not a one-piece chunk of hardware, and it has plenty of connection points, especially in the area that links the shield to the spacecraft, but also on the compression pad, the place that ties together the habitat area of the Orion to the service module.

It is this exact compression pad that got NASA worried during Orion's first test flight back in 2014, as a number of heat-related issues were uncovered. Avcoat was not the way to fix them, and neither was any other material in existence.

That's how NASA, with help from a wealth of American businesses of various sizes, including Bally Ribbon Mills and San Diego Composites, set out to create a new material altogether.

The stuff is called 3D-MAT, but that's a contraction of the much longer term 3-Dimensional Multifunctional Ablative Thermal Protection System. And it's a material capable of holding "different components of Orion together while withstanding the extremely high temperatures of atmospheric re-entry."

3D-MAT is a woven material in a 3D design, made of quartz yarn and cyanate ester resin. In this structure, the quartz yarns are described as being the "more advanced version of the fiberglass insulation" usually found in attics, while the resin is nothing more than a high-tech glue., if there ever was such a thing.

The material comes together using a specialized loom that packs the quartz yarns close together. Resin is then injected to cement the yarns one next to the other

All of the materials used to create the 3D-MAT are off-the-shelf aerospace materials. They were selected to be part of this critical Orion component because, when combined, they can remain very strong under extreme temperatures.

The material has already been put through its paces as it was deployed on the Orion spacecraft of the Artemis I mission in 2022 – and it worked wonderfully, as we've all seen.

Because of this NASA plans to use 3D-MAT in all subsequent flights to the Moon. But given how it's so revolutionary, it also targets other uses for the material, in both the civilian and military sectors.

We'll have to wait and see what else the stuff will be used for, but chances are we won't have to wait for long. After all, it's not mundane objects NASA bestows with the Invention of the Year title, as it did for the 3D-MAT in 2023.

As it comes down from space and reaches the upper layers of a planet's atmosphere, the spacecraft makes the transition from complete void to an environment that opposes it moving forward.

Because the speed of re-entry is quite high (about 25,000 mph / 40,233 kph in the case of a ship returning from the Moon), the spacecraft rubs against air and other gases in such a way that the area around the ship is exposed to extreme temperatures: as much as 5,000 degrees Fahrenheit (2,760 Celsius). For reference, that's twice as hot as molten lava, and half the temperature on the surface of the Sun.

We've all seen what a problem with the heat shield can cause during the Columbia Space Shuttle disaster. As it departed our world, a piece of Columbia's insulating foam on the external fuel tank broke loose and struck the left wing. The heat-resistant tiles there were damaged, and upon returning from the International Space Station (ISS), they failed, causing the ship to burn up in the atmosphere with seven crew members on board.

The heat shield Orion will use to protect itself is centered around something called Avcoat, an evolution of the material that has been around since the days of the Apollo program.

Avcoat is technically an epoxy resin fixed in a fiberglass honeycomb matrix with a series of additives, and it's not something that can last forever during re-entry. The stuff is called an ablator because it burns off in a gradual and controlled manner, detaching from the ship and taking some of the heat with it.

The Avcoat layer on the Orion measures between one and three inches thick (2.5 to 7.6 cm), and it goes over the carbon fiber skin of the heat shield itself.

But Orion, like any other spaceship in existence, is not a one-piece chunk of hardware, and it has plenty of connection points, especially in the area that links the shield to the spacecraft, but also on the compression pad, the place that ties together the habitat area of the Orion to the service module.

It is this exact compression pad that got NASA worried during Orion's first test flight back in 2014, as a number of heat-related issues were uncovered. Avcoat was not the way to fix them, and neither was any other material in existence.

The stuff is called 3D-MAT, but that's a contraction of the much longer term 3-Dimensional Multifunctional Ablative Thermal Protection System. And it's a material capable of holding "different components of Orion together while withstanding the extremely high temperatures of atmospheric re-entry."

3D-MAT is a woven material in a 3D design, made of quartz yarn and cyanate ester resin. In this structure, the quartz yarns are described as being the "more advanced version of the fiberglass insulation" usually found in attics, while the resin is nothing more than a high-tech glue., if there ever was such a thing.

The material comes together using a specialized loom that packs the quartz yarns close together. Resin is then injected to cement the yarns one next to the other

All of the materials used to create the 3D-MAT are off-the-shelf aerospace materials. They were selected to be part of this critical Orion component because, when combined, they can remain very strong under extreme temperatures.

The material has already been put through its paces as it was deployed on the Orion spacecraft of the Artemis I mission in 2022 – and it worked wonderfully, as we've all seen.

Because of this NASA plans to use 3D-MAT in all subsequent flights to the Moon. But given how it's so revolutionary, it also targets other uses for the material, in both the civilian and military sectors.

We'll have to wait and see what else the stuff will be used for, but chances are we won't have to wait for long. After all, it's not mundane objects NASA bestows with the Invention of the Year title, as it did for the 3D-MAT in 2023.