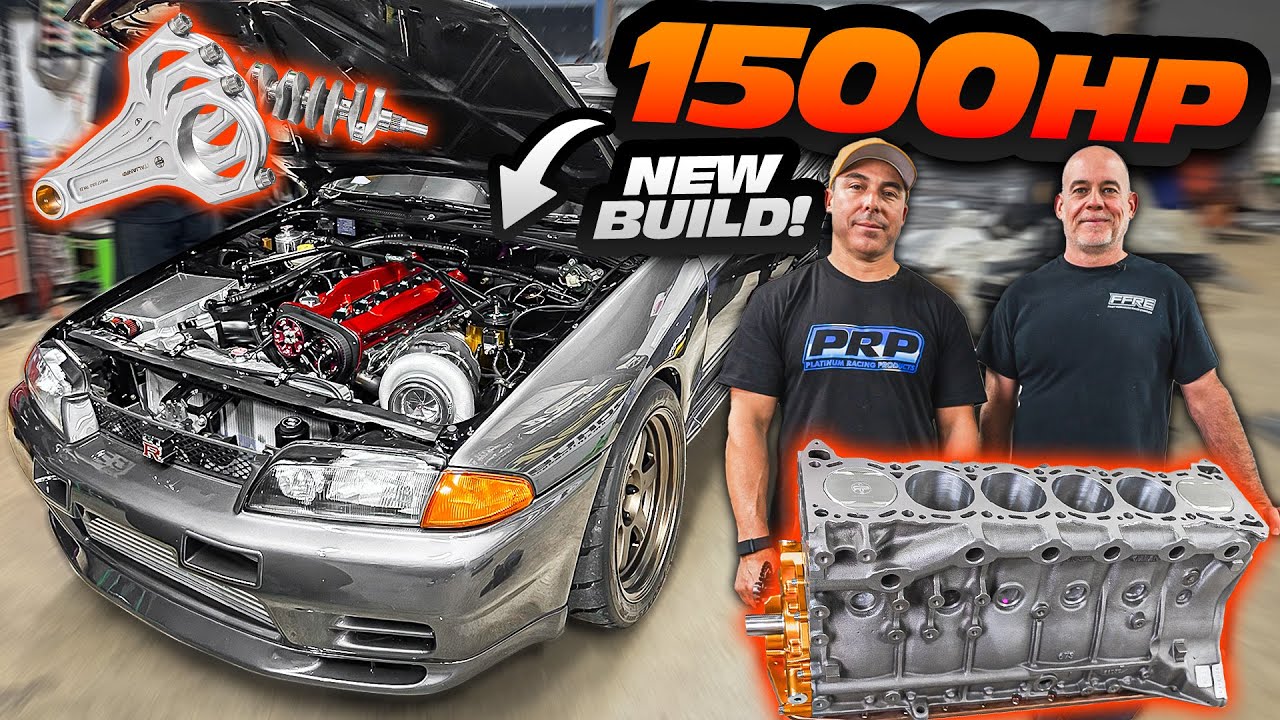

Eighty years ago, you needed an engine nearly the size of an entire car to produce 1,500 horsepower. Back in those days, there really was no replacement for displacement. But many eons have passed since then. As a famous cartoon starfish once said, "we have technology." When we apply some of this 21st-century tech to a 90s JDM classic engine block, you get what the team of Jay Meagger and Herman Urriola have been up to.

As seasoned engine techs from Real Street Performance in Sanford, Florida, and Australia's Platinum Racing Products, respectively, there's perhaps no pair of men on the planet more qualified to squeeze big power out of the classic RB30 engine block than this one. On opposite sides of the globe, these men's two-performance part businesses cater to gearheads who crave high-quality JDM-compatible performance hardware. From JZs to RBs and V-TECs of all varieties, there's very little that's come from Japan in the last 25 years that these two can't wrench on.

So, what can they do with a bare three-liter RB30 67s-series block you'd have found under license in the Aussie-spec late-80s Holden Commodore, R31 Skyline GTR, and GQ-series Nissan Patrol? Well, the answer is to completely re-work its guts, slap even more performance hardware onto it, and add enough forced induction to make as much power as the above-mentioned World War II fighter planes used to make. As it happens, and as Herman explained, one of the biggest hurdles to jump when making big power on the RB platform is fixing notorious oiling issues that still permeate online forums to this day.

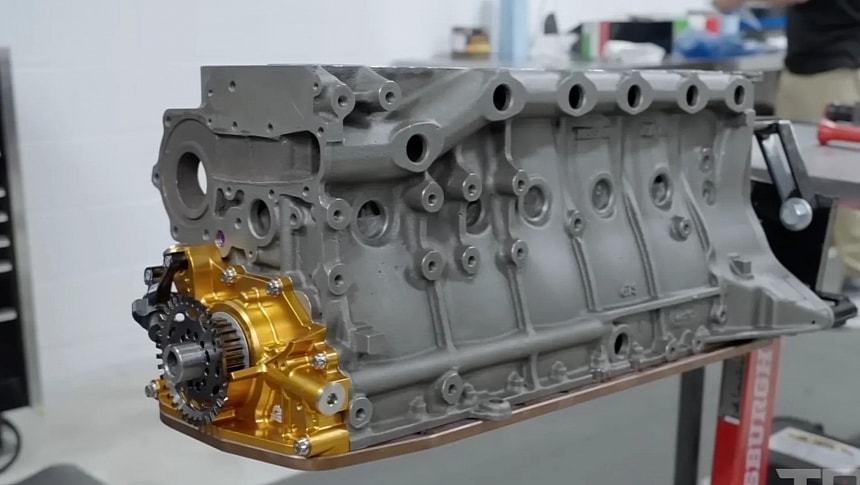

But as the rev-happy Aussie bloke went on to explain, modern DIY fixes have essentially made these problems null and void. Portions of the block on this particular RB engine have been modified with larger passages for oil to flow more freely to engine components under the hardest load and, therefore, the most friction. Using a homemade oil gallery tap and plug set, the factory oil channels go bye-bye while the aftermarket ones take on all the load. Ad on a beefy 90mm crankshaft, more robust IRP pistons, and connecting rods, the higher block deck of the 67s variant means that even larger and more robust hardware can be accepted with relative ease once the oiling is taken care of.

Believe it or not, that extra two mm or so of deck height is enough to make a world of difference to the performance capabilities of this engine. The level of custom machining work needed to make all the clearances needed to not make this engine blow up can not be understated; it's a testament to the special working relationship of this Aussie-American dynamic duo. Custom-threaded head studs and a billet PRP oil pump make for a block that might as well have two extra cylinders with how much fuel and air can move through it.

As the duo assembles the bottom end of this motor on camera, you can't help but salivate at the thought of a matching top end complete with two enormous turbos and a cat-back exhaust to match. It makes you wonder, is 1,500 horses the bottom end of what this motor is capable of or the top? If the former is the case, then this engine will legit be more powerful than all but the most powerful Rolls-Royce Merlins. Only a lack of wings keeps it from taking off like a Spitfire or P-51 Mustang at this point.

So, what can they do with a bare three-liter RB30 67s-series block you'd have found under license in the Aussie-spec late-80s Holden Commodore, R31 Skyline GTR, and GQ-series Nissan Patrol? Well, the answer is to completely re-work its guts, slap even more performance hardware onto it, and add enough forced induction to make as much power as the above-mentioned World War II fighter planes used to make. As it happens, and as Herman explained, one of the biggest hurdles to jump when making big power on the RB platform is fixing notorious oiling issues that still permeate online forums to this day.

But as the rev-happy Aussie bloke went on to explain, modern DIY fixes have essentially made these problems null and void. Portions of the block on this particular RB engine have been modified with larger passages for oil to flow more freely to engine components under the hardest load and, therefore, the most friction. Using a homemade oil gallery tap and plug set, the factory oil channels go bye-bye while the aftermarket ones take on all the load. Ad on a beefy 90mm crankshaft, more robust IRP pistons, and connecting rods, the higher block deck of the 67s variant means that even larger and more robust hardware can be accepted with relative ease once the oiling is taken care of.

Believe it or not, that extra two mm or so of deck height is enough to make a world of difference to the performance capabilities of this engine. The level of custom machining work needed to make all the clearances needed to not make this engine blow up can not be understated; it's a testament to the special working relationship of this Aussie-American dynamic duo. Custom-threaded head studs and a billet PRP oil pump make for a block that might as well have two extra cylinders with how much fuel and air can move through it.

As the duo assembles the bottom end of this motor on camera, you can't help but salivate at the thought of a matching top end complete with two enormous turbos and a cat-back exhaust to match. It makes you wonder, is 1,500 horses the bottom end of what this motor is capable of or the top? If the former is the case, then this engine will legit be more powerful than all but the most powerful Rolls-Royce Merlins. Only a lack of wings keeps it from taking off like a Spitfire or P-51 Mustang at this point.